Walk into any construction site, manufacturing plant, refinery, or shipyard, and you will notice something almost everything has in common: welds. Welded joints hold our infrastructure together, from skyscrapers and pipelines to railways, bridges, vehicles, and industrial machinery. Because those welds carry enormous loads and endure harsh conditions, their reliability is non-negotiable. A single defective weld can compromise an entire structure, lead to costly downtime, or, in the worst situations, put lives at risk.

That is why welding inspection remains one of the most critical responsibilities in engineering. It ensures every welded joint meets safety standards, design requirements, and long-term durability expectations. But welding inspection is not a single step in a project. It involves planning, testing, documentation, and continuous monitoring. The more complex the structure, the more thorough the inspection must be.

Today, engineers have access to a wide spectrum of techniques, tools, and technologies that help evaluate weld quality with precision. Understanding these methods not only strengthens project outcomes but also helps teams prevent future failures before they occur.

Why Welding Inspections Matter in Engineering

At first glance, a weld may seem smooth and solid, but visual appearance alone does not guarantee strength or integrity. Weld defects are often invisible. Tiny cracks, gas pockets, lack of fusion, or inclusions may lie beneath the surface. Over time, those imperfections develop into fractures, leaks, or structural weaknesses. Inspections help identify these issues early so they can be corrected before a system goes into service.

Welding inspections also support regulatory compliance. Industries such as aerospace, oil and gas, construction, and automotive must follow strict codes, including AWS, ASME, API, ISO, and federal safety regulations. Proper inspection ensures every weld meets those standards.

Finally, inspection protects financial investment. Correcting a weld during fabrication costs far less than repairing a completed structure, pausing operations, or dealing with warranty claims. Prevention always beats emergency repairs.

The Role of Qualified Inspectors

Welding inspection is not a task assigned randomly. Skilled inspectors bring specialized knowledge in metallurgy, welding processes, heat treatment, safety standards, and failure analysis. Most hold certifications such as CWI (Certified Welding Inspector), CSWIP, or API credentials.

Inspectors review drawings, verify welder qualifications, check material certifications, confirm correct welding procedures, and monitor environmental conditions. Their expertise helps ensure weld quality even before testing begins.

Most Common Welding Inspection Techniques

Engineers choose inspection methods based on application, material type, weld thickness, and project risk level. Below are some of the most widely used techniques:

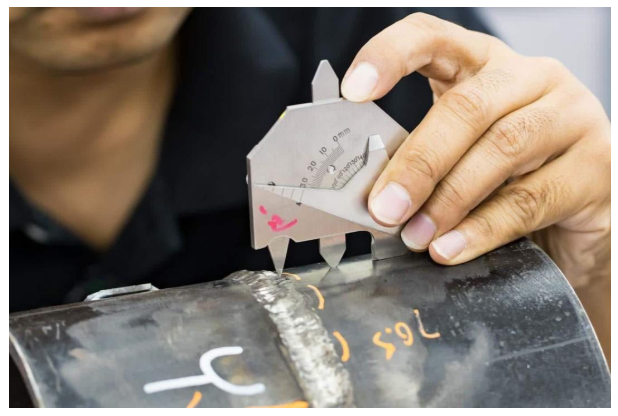

Visual Testing (VT)

This is the first and most cost-efficient step. Inspectors examine welds using the naked eye, magnifiers, mirrors, borescopes, and lighting tools. They look for:

- Undercuts

- Porosity

- Incorrect bead profile

- Surface cracks

- Spatter or slag

While simple, visual inspection can identify many potential issues and guide additional testing.

Radiographic Testing (RT)

Radiographic testing uses X-rays or gamma rays to create an internal image of the weld. It detects subsurface defects such as porosity, inclusions, and cracks. RT is popular in pipeline, structural steel, and pressure vessel fabrication. It requires trained operators and strict safety processes.

Ultrasonic Testing (UT)

Ultrasonic waves travel through the weld, and inspectors analyze how the sound reflects back. UT can reveal internal flaws, thickness variations, and incomplete fusion. It is highly accurate and widely used for critical welds in aerospace and energy sectors.

Magnetic Particle Testing (MT)

This method is ideal for detecting surface and slightly subsurface cracks in ferromagnetic materials like carbon steel. Inspectors magnetize the weld area and apply iron particles, which cluster around defects, making them easy to identify.

Dye Penetrant Testing (PT)

PT works well on non-porous metals, plastics, and ceramics. A colored or fluorescent dye is applied to the weld, allowed to seep into cracks, and then pulled back to the surface with a developer. This exposes surface-level defects clearly.

Acoustic Emission Testing (AET)

A newer technique, acoustic testing detects sound waves released when a material deforms or cracks under stress. It is valuable for real-time monitoring of large structures such as bridges and storage tanks.

Destructive Testing

Sometimes, inspectors deliberately cut, bend, or break welded samples to analyze:

- Tensile strength

- Hardness

- Impact resistance

- Microstructure

Though unusable afterward, destructive testing offers valuable insight into weld performance and manufacturing consistency.

Technology Is Transforming Welding Quality

Modern inspection now includes drones, robotic scanners, laser profiling, digital radiography, and AI-driven defect recognition. Automation improves accuracy, prevents human error, and speeds reporting. Machine learning systems can compare thousands of weld images, detect subtle patterns, and forecast potential failures.

Digital inspection records also support traceability, insurance requirements, and compliance audits. Combined with preventive maintenance programs, these tools improve safety across entire facilities.

Inspections Start Long Before Welding Begins

One common misconception is that welding inspection only happens after the weld is completed. In reality, preparation matters just as much. Engineers must review design drawings, joint details, welder certifications, welding procedures, filler materials, shielding gas type, temperature ranges, and equipment condition. Documentation ensures the weld will meet required performance levels.

Pre-weld inspections also verify proper surface cleaning, beveling, fit-up, and alignment. These small steps greatly reduce the risk of defective welds.

Inspections Play a Key Role in Broader Quality Systems

Welding quality is interconnected with sourcing, materials, fabrication, training, and environmental conditions. That is why many companies perform a Manufacturing process audit to evaluate whether suppliers and in-house teams follow approved welding procedures, safety controls, and compliance guidelines.

When the entire process is monitored, weld quality becomes predictable rather than uncertain.

Safety, Ethics, and Responsibility

Welding inspection is not just a technical requirement. It is a commitment to public safety. Bridges, power plants, ships, and factories must withstand decades of heavy use. When inspections are rushed or ignored, the consequences can be devastating.

Inspectors must uphold honesty and accuracy in reporting. Fabricators must support transparency and continuous improvement. Engineers must prioritize long-term structural safety over immediate deadlines.

Final Thoughts

Welding remains essential to nearly every major industry, and so does inspection. Without reliable testing and documentation, welds cannot be trusted to carry loads, endure weather, or resist corrosion. The right inspection technique ensures durability, protects workers, prevents catastrophic failures, and strengthens project outcomes.

As technology advances, inspection methods will continue to evolve, becoming faster, smarter, and more predictive. But the purpose stays the same. Protect people, protect assets, and ensure every weld performs the way it was designed to.

Whether you are a plant manager, design engineer, contractor, or fabricator, investing in thorough Welding Inspection practices today means fewer risks tomorrow, greater confidence in your structures, and a safer world for everyone who depends on them.