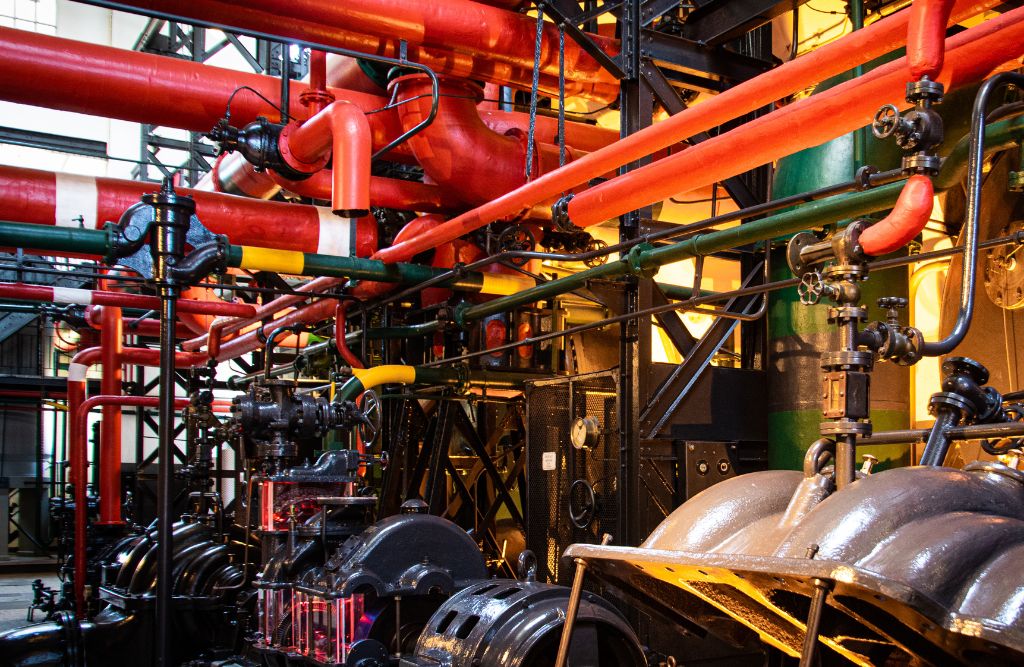

In modern industrial environments, reliability is everything. Whether in oil and gas, chemical processing, water treatment, or manufacturing, the performance of rotating equipment directly affects productivity, safety, and operating costs. At the heart of this reliability lies a critical yet often overlooked discipline: Mechanical Seal Engineering. From preventing leaks to extending equipment life, well-designed sealing systems play a decisive role in keeping operations running smoothly.

This article explores how advanced sealing solutions support pumps, compressors, and other rotating equipment, the challenges engineers face, and how smart engineering choices can deliver long-term value.

Understanding the Role of Mechanical Seals in Rotating Equipment

Mechanical seals are designed to prevent fluid leakage between rotating and stationary components. In pumps and compressors, they protect against product loss, environmental contamination, and equipment damage. Unlike traditional packing systems, mechanical seals offer superior sealing performance, reduced friction, and longer service life.

Effective Mechanical Seal Engineering considers not only the seal itself but also the entire operating environment. Pressure, temperature, shaft speed, fluid properties, and alignment all influence seal performance. When these factors are ignored, even the best materials can fail prematurely.

In high-demand industries, sealing systems are no longer standard components—they are engineered solutions tailored to specific applications.

Key Challenges in Pumps, Compressors, and Rotating Machinery

Rotating equipment operates under harsh conditions that place continuous stress on sealing systems. Some of the most common challenges include:

- High pressures and temperatures that degrade seal materials

- Abrasive or corrosive fluids that cause rapid wear

- Shaft misalignment and vibration that disrupt sealing faces

- Frequent start-stop cycles that increase mechanical fatigue

Without proper design, these factors lead to leakage, unplanned downtime, and costly maintenance.

This is where professional Mechanical Seal Engineering becomes essential. Engineers must evaluate both the mechanical and chemical environment before selecting materials, face combinations, and support systems.

Custom Seal Design: One Size Does Not Fit All

Every application is unique. A seal designed for a clean water pump will not perform well in a slurry pipeline or a high-speed compressor. Custom design allows engineers to optimize:

- Seal face materials (carbon, silicon carbide, tungsten carbide)

- Elastomers compatible with process fluids

- Spring configurations for stable loading

- Cooling and flushing systems to control temperature

Advanced Mechanical Seal Engineering integrates simulation tools, material science, and field experience to create seals that perform reliably under real-world conditions.

By tailoring designs to specific operating parameters, engineers can significantly reduce leakage rates and extend maintenance intervals.

Improving Reliability and Reducing Downtime

Unplanned equipment failure is one of the most expensive problems in industrial operations. A single seal failure can shut down an entire production line. That’s why modern maintenance strategies increasingly rely on predictive and condition-based monitoring.

High-quality Mechanical Seal Engineering focuses on reliability-centered design. This includes:

- Selecting seals with appropriate safety margins

- Designing for stable lubrication films between faces

- Minimizing heat generation and distortion

- Incorporating monitoring ports and sensors

When seals are engineered correctly from the start, plants benefit from fewer breakdowns, lower spare parts consumption, and improved safety.

Seal Support Systems: The Hidden Performance Booster

The seal itself is only part of the system. Support systems—such as flush plans, barrier fluids, and cooling circuits—play a critical role in extending seal life.

Common support strategies include:

- Single seal flush systems to remove heat and debris

- Dual seals with barrier fluid for hazardous or toxic media

- Quench systems to prevent crystallization or coking

- Thermosiphon loops for passive cooling

Effective Mechanical Seal Engineering ensures that these systems are properly designed, installed, and maintained. Poor support system design is one of the leading causes of premature seal failure.

Materials and Technology Advancements

Seal technology has evolved significantly in recent decades. New materials and manufacturing methods have expanded the performance envelope of mechanical seals.

Some notable advancements include:

- High-purity silicon carbide for extreme wear resistance

- Advanced carbon composites for dry-running capability

- Laser-welded metal bellows for high-temperature service

- Precision lapping for ultra-flat sealing faces

Through continuous innovation, Mechanical Seal Engineering now supports applications that were once considered too extreme for conventional seals.

These improvements translate into longer seal life, lower leakage, and reduced environmental impact.

Application-Specific Solutions

Different industries demand different sealing strategies.

Pumps:

In centrifugal and positive displacement pumps, seals must handle fluctuating pressures and flow rates. Proper face balance and cooling are critical to prevent thermal distortion.

Compressors:

High-speed compressors require seals with excellent dynamic stability. Gas seals and non-contacting designs are often preferred to minimize friction and wear.

Mixers and Agitators:

These systems experience significant shaft deflection and vibration. Engineered cartridge seals with robust hardware are commonly used.

In each case, Mechanical Seal Engineering adapts design principles to meet the unique mechanical and chemical demands of the equipment.

Installation and Maintenance: Engineering Beyond Design

Even the best seal design can fail if installed incorrectly. Common installation issues include:

- Improper shaft alignment

- Contaminated sealing faces

- Incorrect setting dimensions

- Inadequate flushing or cooling

Professional Mechanical Seal Engineering includes clear installation procedures, training programs, and commissioning support. Proper handling during installation can double or triple seal service life.

Ongoing maintenance is equally important. Routine inspection, fluid monitoring, and vibration analysis help detect early warning signs before catastrophic failure occurs.

Environmental and Regulatory Considerations

Leak prevention is no longer just a maintenance issue—it is a regulatory requirement. Many industries face strict environmental and safety standards regarding fugitive emissions and hazardous fluid handling.

Modern Mechanical Seal Engineering supports compliance by:

- Designing zero-leakage sealing systems

- Using dual seals with monitored barrier fluids

- Integrating leak detection systems

- Selecting materials that minimize emissions

These solutions protect not only equipment but also workers, communities, and the environment.

Choosing the Right Engineering Partner

Selecting a sealing solution provider is a strategic decision. The right partner offers more than products—they deliver engineering expertise, field support, and continuous improvement.

When evaluating suppliers, consider:

- Application engineering capability

- Experience in your industry

- Testing and validation facilities

- After-sales service and training

A strong Mechanical Seal Engineering partner helps you move from reactive maintenance to proactive reliability management.

Conclusion

Mechanical seals may be small components, but their impact on industrial performance is enormous. From preventing leaks and reducing downtime to improving safety and compliance, engineered sealing solutions are essential for modern rotating equipment.

Through thoughtful design, advanced materials, proper support systems, and expert installation, Mechanical Seal Engineering transforms sealing from a weak point into a strategic advantage.

As industries continue to push equipment harder and operate under stricter regulations, the role of sealing engineers will only become more critical. Investing in engineered sealing solutions today is an investment in reliability, efficiency, and long-term operational success.