Gear manufacturing is a critical consideration when it comes to modern machinery and engineering. In the fast-paced gear manufacturing world, accuracy and efficiency are mandatory for gaining a competitive edge. The right gear hob cutters are crucial to make the hobbing process smooth. A gear manufacturer uses such a cutter to attain a remarkable outcome.

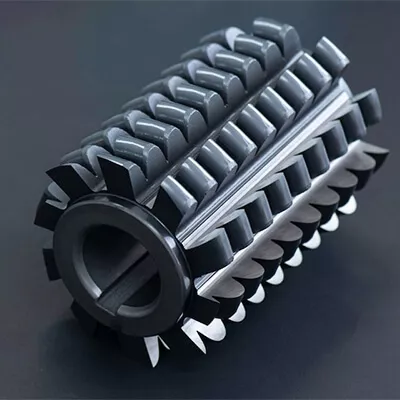

Gear hobbing is a wonderful technique in gear manufacturing. A hob cutter is a specialized tool to handle the hobbing operation. Such a technique involves cutting gear teeth into a cylindrical blank. It is crucial for precise spline, spur gear, worm gear, and helical gear.

It serves as a continuous process that gives more efficiency and flexibility, unlike other production methods. It is high in demand in many industries where performance and reliability are vital, including aerospace, industrial machinery, and automotive.

Different forms of cutters for hobbing:

For precision gear manufacturing, an expert is responsible for choosing the ideal cutter and performing the hobbing process. In the market, different forms of hob cutters are available for specific applications.

-

Helical hob cutter

It is a special tool for cutting helical gears that come with angled teeth. It is reliable for smooth operation and extreme load capacity.

-

Straight hob cutter

A straight hob cutter is great for cutting straight teeth and is popular for its effectiveness and simplicity.

-

Custom hob cutter

It is the most demanding cutter option for specialized gear. Custom cutter fulfills specific requirements and guarantees optimal performance.

-

Spiral hob cutter

A spiral hob cutter is a good choice for complex profiles and works well on high-precision applications.

Boost production efficiency

A gear manufacturer uses this method to enhance production efficiency. The right hob cutter is the best companion for a manufacturer to carry out hobbing efficiently. With the best gear hob manufacturers, experts get quality tools to deal with the process efficiently.

During gear making, experts spend a few minutes on setup. It requires simple modification and an assembly tool to quickly. It is particularly helpful for batch production where downtime minimization is crucial.

-

Attain constant quality

In modern gear manufacturing, CNC is a crucial part of the hobbing process. It ensures that each piece of gear meets an accurate quality standard with less variance and minimizes rework and scrap.

-

Smart manufacturing integration

A smart manufacturing system can integrate a modern hobbing tool. Tool usage and productivity can be enhanced with smart integration. It is better to keep track of hob wear and cutting condition in real time.

Versatility in gear type

By moving out the cutter, the hob gives complete versatility to generate different forms of gear. It produces gears from huge industrial gears to tiny gears.

Manufacturers pay attention to these matters to boost efficiency. Integrating an efficient hob cutter is better to meet hobbing requirements. When choosing a cutter, they focus on gear type, workpiece material, tool compatibility, and gear quality grade. Reputable providers offer a tailored solution for the hobbing operation. So, you can consult an expert today and acquire the ideal tool to streamline the production line.